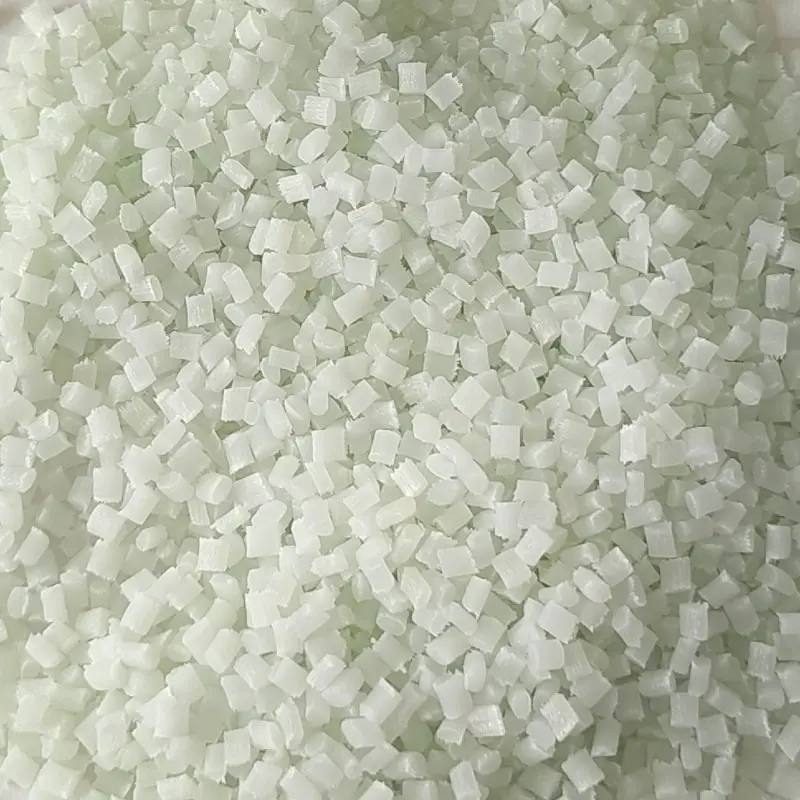

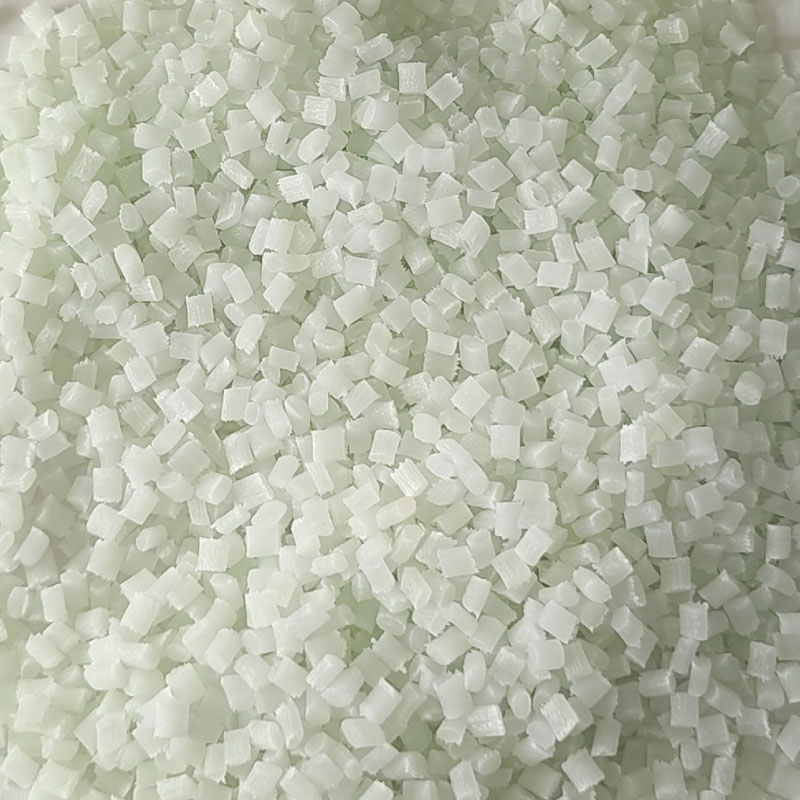

| Resin Identification | PPA GF30+15%PTFE Reinforced, Wear-resistant, Heat-stabilized grade Internally lubricated | |||

| Color | Natural or Typical Colors | |||

| Main applications | Electrical components, locomotive components, automotive components | |||

| Processing Method | Injection Molding | |||

| Typical Properties | Test Method | Test Condition | Value | Unit |

| Physical Properties | ||||

| Density | DIN EN ISO 1183 | 23 °C | 1.55 | g/cm3 |

| Water Absorption | ASTM D570 | 50RH 24hr | 0.3 | % |

| Shrinkage | GB 15585 | 0. 2-0.4 | % | |

| Mechanical Properties | ||||

| Tensile Strength | DIN EN ISO 527 | 50mm/min | 190 | MPa |

| Elongation at Break | 2.5 | % | ||

| Flexural Strength | DIN EN ISO 178 | 2mm/min | 290 | MPa |

| Flexural Modulus | 11000 | MPa | ||

| Tensile modulus | DIN EN ISO 527 | 5mm/min | 9800 | MPa |

| Izod Notched Impact Strength | DIN EN ISO 180 | 4mm,23 ℃ | 12. 5 | KJ/M2 |

| The cantilever beam has no lack of impact strength | DIN EN ISO 180 | 4mm,23 ℃ | 100 | KJ/M2 |

| Friction Coefficient | ASTM D3702 | Dynamic | 0.46 | |

| Friction Coefficient | ASTM D3702 | Static | 0.49 | |

| Thermal Performance | ||||

| Heat Deformation Temperature | DIN EN ISO 75 | 1.8MPa | 270 | ℃ |

| Heat Deformation Temperature | DIN EN ISO 75 | 0.45MPa | 295 | ℃ |

| Vika softens | DIN EN ISO 306 | 120℃/hr 50N | 310 | ℃ |

| Others | ||||

| Flame-retardant properties | UL94 | 0.75-3mm | HB | |

| Glow wire flammability index | IEC60695-2-12 | 0.75mm | 650 | ℃ |

| Glow wire flammability index | IEC60695-2-12 | 1.5mm | 650 | ℃ |

| Glow wire flammability index | IEC60695-2-12 | 3mm | 750 | ℃ |

| Glow wire flammability index | IEC60695-2-13 | 0.75mm | 650 | ℃ |

| Glow wire flammability index | IEC60695-2-13 | 1.5mm | 650 | ℃ |

| Glow wire flammability index | IEC60695-2-13 | 3mm | 750 | ℃ |

Note:

(1) The data are typical values, only as a reference for customers’ use, not as a guarantee of the minimum or maximum value of the quality indicators and any other use.

(2) Performance may vary with different colors.

| Typical Injection Molding Process | |

| Plastic Drying | |

| Drying Time | 3~4 hour |

| Drying Temperature | 120~140℃ |

| Drying Equipment | Hot Air Dryer |

| Drying Type | Continuous drying (production process) |

| Injection Molding Process | |

| Nozzle Section | 320~340℃ |

| Plastics Section | 310~330℃ |

| Conveying Section | 290~310℃ |

| Maximum Injection Temperature | 360℃ |

| Injection Pressure | 60~120MPa |

| Injection Speed | 30~75mm/s |

| Plasticization PressureVelocity | Pressure 65~100MPa, Velocity 60-85mm/s |

| Plasticization Back Pressure | 10~40MPa |

| Recommended Mold Temperature | 150~170℃ |

Note:

The above injection molding process should be based on the shape of the product, mold design, and injection molding machine specifications, and other conditions are different, the specific parameters should be adjusted according to the actual situation.

EN

EN English

English 中文简体

中文简体 Español

Español